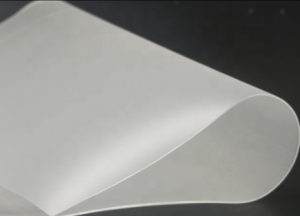

In the vast field of materials science, TPU film is gradually emerging as a focus of attention in numerous industries due to its unique properties and extensive applications. TPU film, namely thermoplastic polyurethane film, is a thin film material made from polyurethane raw materials through special processes. Its molecular structure contains both flexible segments and rigid segments, and this unique structure endows TPU film with a series of excellent properties, making it show unparalleled advantages in many fields.

Performance Advantages of TPU Film

Excellent Mechanical Properties

One of the most significant advantages of TPU film is its excellent mechanical properties, which combines high strength and high elasticity. The tensile strength can generally reach 20-50MPa, and some enhanced models even exceed 60MPa. The elongation at break can reach 300%-1000%, and the elastic recovery rate is over 90%. This means that even if the TPU film is stretched several times its original length, it can quickly return to its original shape after being released, with almost no permanent deformation. For example, in the production of sports shoes, TPU film, as a shoe upper material, can flexibly stretch with the movement of the foot, providing a comfortable wearing experience while maintaining good shape and support.

This “combination of rigidity and flexibility” stems from the synergistic effect of hard segments (isocyanate segments) and soft segments (polyol segments) in its molecular chain. The hard segments form physical cross-linking points, like steel bars in buildings, providing strength support for the material; the soft segments, like springs, endow the material with elasticity. The ratio of the two can be precisely adjusted through formula adjustment, so as to meet the diverse needs from “high elasticity close to rubber” to “high strength similar to engineering plastics”.

In addition, TPU film also has excellent tear resistance and wear resistance. The right-angle tear strength is ≥40kN/m, and the wear loss is ≤5mg/1000 times, which is far better than traditional film materials such as PVC and PE. In the field of outdoor sports equipment, such as the carrying system of mountaineering backpacks and the edge protection of ski boards, the high tear resistance and wear resistance of TPU film can effectively extend the service life of products and withstand the test of harsh environments.

Excellent Environmental Resistance

TPU film performs well in terms of environmental resistance and can adapt to various complex environmental conditions. In terms of temperature resistance, it can maintain stable performance in a wide temperature range of -40℃ to 80℃. In low-temperature environments, the soft segments do not crystallize, avoiding brittle fracture of the material; in high-temperature environments, the hard segments do not melt, maintaining the structural strength of the material. This characteristic enables TPU film to be used in cold polar regions, such as making waterproof and breathable layers for polar expedition suits, and also to play a role in hot desert environments, such as heat insulation protective films in automobile engine compartments.

At the same time, TPU film has outstanding weather resistance. After 1000 hours of ultraviolet aging test, the attenuation rate of its tensile performance is only 10%-15%, which is much lower than that of PVC film (more than 50%). Moreover, it is not sensitive to humidity changes, and when used in an environment with a relative humidity of 90% for a long time, the performance fluctuation can be controlled within 5%. Therefore, TPU film is very suitable for outdoor building materials, such as sunshades and building membrane structures, which can resist the erosion of ultraviolet rays, wind, rain and humidity for a long time and maintain good performance and appearance.

Good Chemical Stability and Functional Diversity

TPU film has good resistance to common media such as water, oil, acid and alkali. After being soaked in water for 30 days, the tensile performance decreases by no more than 8%; after contact with engine oil, detergent, etc., there is no swelling or cracking, while PVC film is easy to swell when exposed to oil, and PE film will be eroded by organic solvents. Based on this characteristic, the surface of TPU film can be modified in various ways. For example, frosting treatment can improve skid resistance, which is used to make protective cases for electronic products; coating with an antibacterial layer can enhance hygiene performance, which is applied to the surface protection of medical equipment; compounding with a hydrophilic coating can improve air permeability, which is used to make fabrics for sportswear, etc. Moreover, these modification treatments basically do not affect the original mechanical properties of TPU film.

In addition, the barrier performance of TPU film can be adjusted as needed. By changing the density and microporous structure, it can be made into a highly breathable film for clothing and medical fields, allowing human skin to breathe freely, and also can produce a highly airtight film for inflatable products, waterproof packaging, etc., ensuring that gas or liquid will not leak. For example, in inflatable water park facilities, TPU high-airtightness film can ensure the stable inflation state of the facilities and provide a safe and reliable entertainment experience; in medical wound dressings, highly breathable TPU film can not only prevent bacterial invasion but also promote gas exchange during wound healing.

Processing Convenience and Environmental Protection Advantages

TPU film has good processing performance and can be made into products with different thicknesses (0.01-2mm) through various processes such as extrusion, blow molding and casting. Moreover, it is easy to carry out secondary processing such as heat sealing, high-frequency welding, cutting and sewing, with the joint strength reaching more than 90% of the base material itself, and the processing efficiency is 30%-50% higher than that of rubber film. In the process of making luggage, TPU film can be quickly and firmly combined with other materials through heat sealing technology to produce luggage parts with waterproof and wear-resistant functions.

In terms of environmental protection, TPU film performs excellently. Its production process does not contain toxic plasticizers such as phthalates. After being discarded, it can be 100% recycled and remolded. When burned, it only releases CO₂ and H₂O, without pollutants such as dioxins, and meets strict environmental protection standards such as EU RoHS and REACH. This makes TPU film an ideal choice to replace non-environmentally friendly materials such as PVC, and has great development potential in today’s society that pays attention to environmental protection. For example, in the field of food packaging, the environmental protection characteristics of TPU film enable it to safely contact food, ensure consumers’ health, and reduce environmental pollution.

Application Fields of TPU Film

Medical Field

Due to its good biocompatibility and physical properties, TPU has been widely used in the medical field. It can be used to make high-end medical products such as artificial heart assist devices, artificial blood vessels, and artificial skin. For example, artificial blood vessels need to have good flexibility, strength and anticoagulability. TPU film just meets these requirements, can simulate the elasticity and mechanical properties of human blood vessels, reduce the risk of thrombosis, and improve patients’ quality of life.

TPU film can also be used to manufacture coatings for surgical instruments to reduce friction between instruments and tissues and reduce surgical trauma; to make artificial heart valves to ensure stable and reliable opening and closing functions of the valves; and to be applied in drug delivery systems to achieve more effective therapeutic effects by precisely controlling the drug release rate. It can be said that TPU film provides important material support for the development of medical technology and promotes innovation and progress in the medical field.

Footwear Industry

In the footwear industry, TPU plastic film is favored for its good toughness and wear resistance. It is widely used in the production of various shoe styles such as sports shoes, mountaineering shoes and ski shoes. As a shoe upper material, TPU film can not only provide excellent support and protection to prevent the shoe upper from deformation but also flexibly stretch according to the movement of the foot to enhance the comfort of the shoes. For example, some high-end sports shoes use a composite fabric of TPU film and textiles, which has both waterproof and breathable functions and can show a unique and fashionable appearance.

In the sole part, TPU film can be used to make the supporting structure or decorative parts of the sole, improve the wear resistance and tear resistance of the sole, and extend the service life of the shoes. At the same time, TPU film can also be made into various shapes of shoe material accessories through injection molding and other processes, such as heels and shoelace buckles, adding more design possibilities and functionality to footwear products.

Electronic Product Protection

With the popularization of electronic products, the demand for their protection is also increasing. The strength of TPU film can be adjusted according to the actual situation, making it very suitable for the protective case design scheme of new 3C products. It can be used to make protective films, keyboard stickers, mobile phone cases, etc., for electronic products, effectively protecting the outer shell of electronic products from scratches, collisions and daily wear and tear.

The flexibility and transparency of TPU film allow it to protect electronic products without affecting the normal operation and visual effect of the equipment. For example, mobile phone screen protectors made of TPU material can fit the surface of the screen, provide a good touch feeling, and have anti-fingerprint and anti-glare functions to improve user experience. In addition, TPU film also has a certain buffering performance, which can absorb part of the impact force when electronic products are accidentally dropped, reducing damage to internal components.

Pipeline Industry

The flexibility and aging resistance of TPU film give it unique advantages in the pipeline industry, especially in environments where corrosion and oxidation need to be avoided. It can be used to manufacture various liquid or gas transmission pipelines, such as chemical pipelines, food and beverage transmission pipes, automobile fuel pipes, etc. TPU film pipelines can resist the erosion of various chemical substances, ensuring the safety of the transmitted medium and the long-term stable operation of the pipelines.

In some special application scenarios, such as submarine oil pipelines, TPU film can work reliably in harsh marine environments with its good water pressure resistance and seawater corrosion resistance. Compared with traditional metal pipelines, TPU film pipelines have the advantages of light weight, convenient installation and low cost, and can also effectively reduce the risk of pipeline leakage and improve transmission efficiency.

Packaging Industry

In the packaging industry, the flexibility and tear resistance of TPU film make it an ideal choice for protecting packaged materials from damage and pollution. It is often used in fields such as food packaging, pharmaceutical packaging and industrial product packaging. In terms of food packaging, TPU film has good flexibility, can closely fit the shape of food, realize vacuum packaging or nitrogen-filled packaging, and extend the shelf life of food. At the same time, its tear resistance can prevent packaging from breaking during handling and storage, ensuring food safety and hygiene.

For pharmaceutical packaging, the chemical stability and barrier performance of TPU film are crucial. It can effectively block the invasion of oxygen, moisture and microorganisms, protecting the quality and efficacy of drugs. In addition, TPU film can also achieve exquisite packaging design through printing and compounding processes, enhancing the market competitiveness of products.

Other Industrial Applications

TPU plastic film can be used to make inflatable materials, such as lifeboats and airbags. In the manufacture of lifeboats, the high airtightness and high strength of TPU film ensure that lifeboats can maintain good floating performance and load-bearing capacity on the water, providing safety guarantee for distressed personnel. The TPU film in the airbag is required to be able to withstand huge impact force in an instant and have good gas barrier performance to ensure that the airbag can inflate quickly and remain stable, effectively protecting the safety of drivers and passengers.

In the construction field, TPU film can be applied to building covering and isolation materials. For example, as a roof waterproof layer, TPU film can provide excellent waterproof performance, resist rainwater penetration, and its weather resistance can ensure that it does not age or crack in the outdoor environment for a long time. In building membrane structures, the high strength and flexibility of TPU film enable it to shape various unique architectural shapes, adding artistic charm to modern buildings.

In the automotive and aviation fields, TPU film is also widely used. In terms of automotive interiors, it can be used to make seat covers, floor mats, door trim panels, etc., providing a comfortable touch and good wear resistance. In the manufacture of automotive exterior parts, the weather resistance and chemical corrosion resistance of TPU film can ensure the long-term beauty and stable performance of the automotive appearance. In the aviation field, TPU film can be used for the decoration and protection of aircraft interiors, as well as the manufacture of some aviation components. Due to its light weight and high strength, it helps to reduce the weight of the aircraft and improve fuel efficiency.

Smart Wear and New Energy

TPU film is widely used in smart wearable devices. Such as the straps and cases of smart bracelets, smart watches and other devices. Because of its good flexibility, wear resistance and biocompatibility, TPU film can fit the human wrist, provide a comfortable wearing experience, and at the same time resist friction and sweat erosion in daily use, ensuring the appearance and performance of the device.

In the field of new energy, TPU film also plays an important role. For example, in solar panels, TPU film can be used as an encapsulation material to protect the battery cells from the external environment, improving the service life and power generation efficiency of the solar panels. In wind turbine blades, TPU film can be used as a protective coating on the blade surface to enhance the weather resistance and wear resistance of the blade, resist the erosion of wind, sand and rain, and ensure the stable operation of the wind turbine.

Daily Necessities

In the field of daily necessities, TPU film can also be seen everywhere. In clothing and textiles, it can be used for clothing linings, fabric coatings, waterproof clothing, etc. For example, waterproof and breathable TPU film applied to outdoor clothing can keep the wearer dry in rainy days and at the same time discharge moisture generated by the body, providing a comfortable wearing feeling. In terms of sporting goods, TPU film is widely used in sports shoes, sportswear, sports equipment, etc., due to its good elasticity and wear resistance. For example, the air cushion part of sports shoes uses TPU film, which can provide excellent shock absorption effect and improve sports performance; the handle part of sports equipment is wrapped with TPU film to increase friction and feel comfort.

The TPU film of Yantai Linghua New Material has shown great application value in many fields with its excellent performance advantages. With the continuous progress and innovation of science and technology, the performance of TPU film will be continuously optimized, and its application range will continue to expand, bringing more opportunities and changes to the development of various industries, and becoming an important force promoting the development of materials science and industrial upgrading.

Post time: Jul-31-2025