TPU film sheet for bags luggage suitcase box

About TPU

Material basis

Composition: The main composition of the bare film of TPU is thermoplastic polyurethane elastomer, which is formed by reaction polymerization of diisocyanate molecules such as diphenylmethane diisocyanate or toluene diisocyanate and macromolecular polyols and low molecular polyols.

Properties: Between rubber and plastic, with high tension, high tension, strong and other

Application advantage

Protect the car paint: the car paint is isolated from the external environment, to avoid air oxidation, acid rain corrosion, etc., in the second-hand car trading, it can effectively protect the original paint of the vehicle and improve the value of the vehicle.

Convenient construction: With good flexibility and stretchability, it can fit the complex curved surface of the car well, whether it is the plane of the body or the part with a large arc, it can achieve tight fitting, relatively easy construction, strong operability, and reduce the problems such as bubbles and folds in the construction process.

Environmental health: The use of environmentally friendly materials, non-toxic and tasteless, environmentally friendly, in the production and use of the process will not cause harm to the human body and the environment.

Application

Stationery, handbags, bags, shoe materials, stationery, tablecloths

Parameters

The above values are shown as typical values and should not be used as specifications.

| Item |

Unit |

Test standard |

Spec. |

|

Thickness |

mm |

GB/T 6672 |

0.3-0.8 |

|

Width deviation |

mm |

GB/ 6673 |

1370mm |

|

Tensile Strength |

Mpa |

ASTM D882 |

≥45 |

|

Elongation at Break |

% |

ASTM D882 |

≥400 |

|

Hardness |

Shore A |

ASTM D2240 |

80-95 |

|

Original place |

|

|

China |

|

Melt point |

℃ |

Kofler |

100±5 |

|

Light transmittance |

% |

ASTM D1003 |

≥90 |

|

Fog value |

% |

ASTM D1003 |

≤2 |

|

Colorfull |

|

|

custom-made |

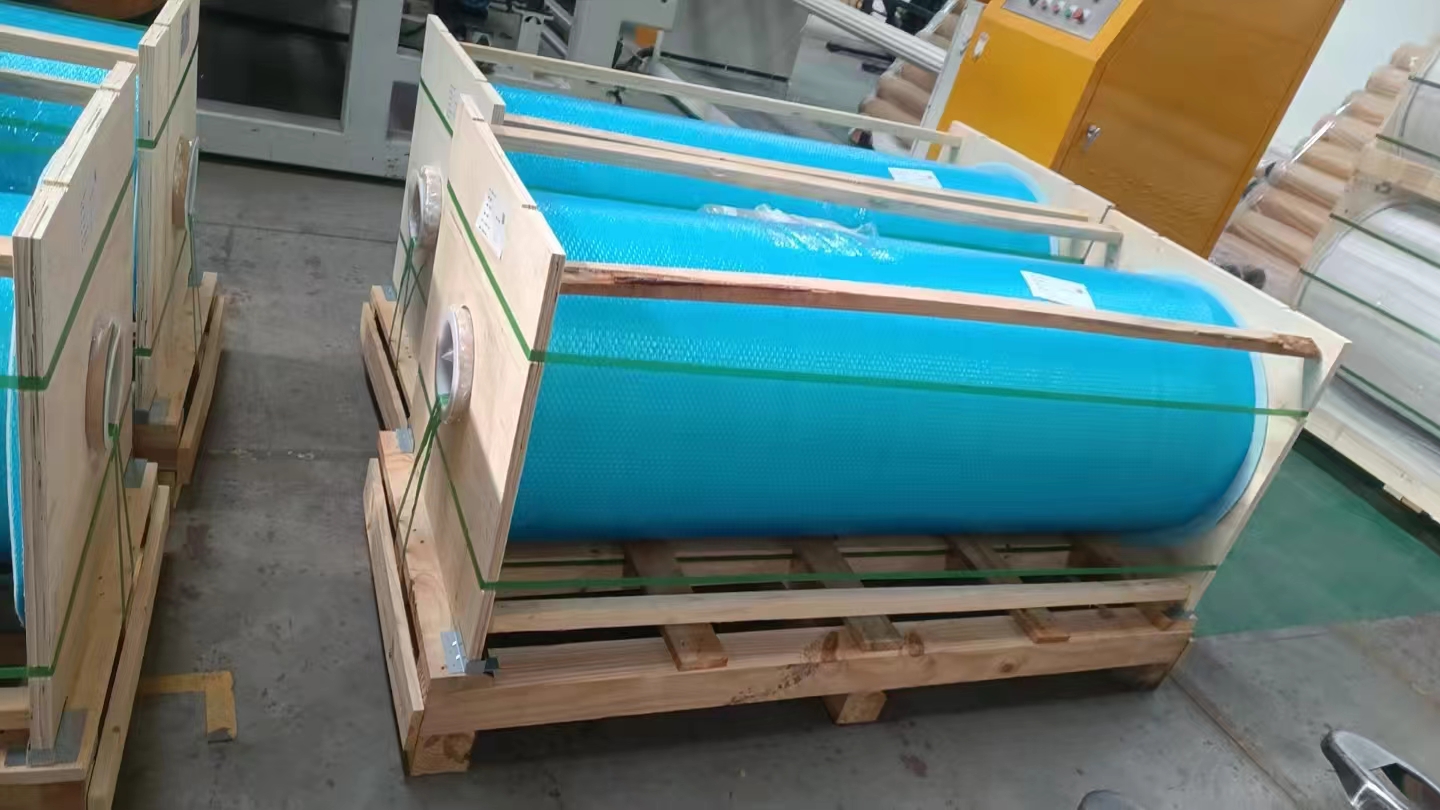

Package

1.56mx0.15mmx900m/roll,1.56x0.13mmx900/roll, processed plastic pallet

Handling and Storage

1. Avoid breathing thermal processing fumes and vapors

2. Mechanical handling equipment can cause formation of dust. Avoid breathing dust.

3. Use proper grounding techniques when handling this product to avoid electrostatic charges

4. Pellets on the floor may be slippery and cause falls

Storage recommendations: To maintain product quality, store product in a cool, dry area. Keep in a tightly sealed container.

Certifications