Organic solar cells (OPVs) have great potential for applications in power windows, integrated photovoltaics in buildings, and even wearable electronic products. Despite extensive research on the photoelectric efficiency of OPV, its structural performance has not yet been so extensively studied.

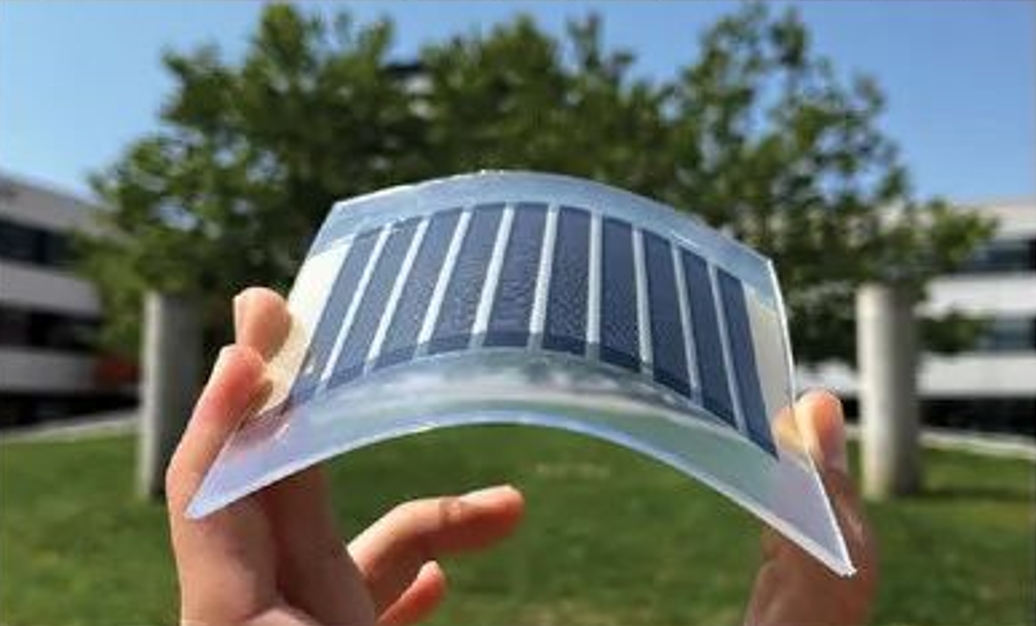

Recently, a team located in the Eurecat Functional Printing and Embedded Equipment Department of the Catalonia Technology Center in Mataro, Spain has been studying this aspect of OPV. They say that flexible solar cells are sensitive to mechanical wear and may require additional protection, such as embedding in plastic components.

They studied the potential of embedding OPVs in injection molded TPU parts and whether large-scale manufacturing is feasible. The entire manufacturing process, including the photovoltaic coil to coil production line, is carried out in an industrial processing line under environmental conditions, using an injection molding process with a yield of approximately 90%.

They chose to use TPU to shape OPV because of its low processing temperature, high flexibility, and wide compatibility with other substrates.

The team conducted stress testing on these modules and found that they performed well under bending stress. The elastic properties of TPU mean that the module undergoes delamination before reaching its ultimate strength point.

The team suggests that in the future, TPU injection molded materials can provide in mold photovoltaic modules with better structure and equipment stability, and may even provide additional optical functions. They believe that it has potential in applications that require the combination of optoelectronics and structural performance.

Post time: Nov-13-2023