Researchers from the University of Colorado Boulder and Sandia National Laboratory in the United States have launched a revolutionary shock-absorbing material, which is a breakthrough development that can change the safety of products from sports equipment to transportation.

This newly designed shock-absorbing material can withstand significant impacts and may soon be integrated into football equipment, bicycle helmets, and even used in packaging to protect delicate items during transportation.

Imagine that this shock-absorbing material can not only cushion the impact, but also absorb more force by changing its shape, thus playing a more intelligent role.

This is exactly what this team has achieved. Their research was published in the academic journal Advanced Material Technology in detail, exploring how we can surpass the performance of traditional foam materials. Traditional foam materials perform well before being squeezed too hard.

Foam is everywhere. It exists in the cushions we rest on, the helmets we wear, and the packaging that ensures the safety of our online shopping products. However, foam also has its limitations. If it is squeezed too much, it will no longer be soft and elastic, and its impact absorption performance will gradually decline.

Researchers from the University of Colorado Boulder and the Sandia National Laboratory conducted in-depth research on the structure of shock-absorbing materials, using computer algorithms to propose a design that is not only related to the material itself, but also to the arrangement of the material. This damping material can absorb about six times more energy than standard foam and 25% more energy than other leading technologies.

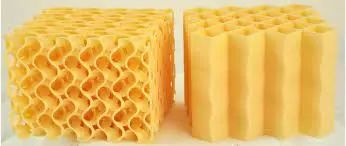

The secret lies in the geometric shape of the shock-absorbing material. The working principle of traditional damping materials is to squeeze all the tiny spaces in the foam together to absorb energy. Researchers used thermoplastic polyurethane elastomer materials for 3D printing to create a honeycomb like lattice structure that collapses in a controlled manner when subjected to impact, thereby more effectively absorbing energy. But the team wants something more universal that can handle various types of impacts with the same efficiency.

To achieve this, they started with a honeycomb design, but then added special adjustments – small twists like an accordion box. These kinks aim to control how the honeycomb structure collapses under force, enabling it to smoothly absorb the vibrations generated by various impacts, whether they are fast and hard or slow and soft.

This is not just theoretical. The research team tested their design in the laboratory and squeezed their innovative shock-absorbing material under powerful machines to prove its effectiveness. More importantly, this high-tech cushioning material can be produced using commercial 3D printers, making it suitable for a wide range of applications.

The impact of the birth of this shock-absorbing material is enormous. For athletes, this means potentially safer equipment that can reduce the risk of collision and fall injuries. For ordinary people, this means that bicycle helmets can provide better protection in accidents. In the broader world, this technology can improve everything from safety barriers on highways to the packaging methods we use to transport fragile goods.

Post time: Mar-14-2024